Tracing

Tracing

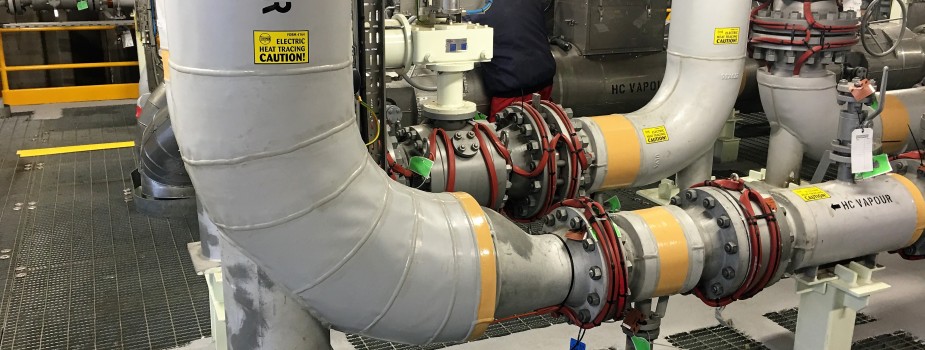

In 98% of the applications tracing is used to compensate for the heat loses through the insulation on a stationary product. Tracing can be divided into two categories:

EW (frost protection) and EP (process)

Frost protection systems are usually controlled by a room thermostat that switches on tracing groups at a temperature below 5C. Process systems are controlled in the line with a pipe thermostat te regulate the temperature accurately and to save energy. In a number of cases it is better to always apply thermostats (even with a self-regulating cable), since the outlet temperature of the system could be higher than expected. This can occur with drinking water pipes, eye and emergency showers.

The performance of a well designed tracing system depends on the quality of the insulation. Self-regulatingheating cables are most commonly used because the installed power is independent of the length to install.

There are several types of self-regulating cables with individual temperature rating (T classification), they are all suitable for use in hazardous area zone 1 and 2.

If you need advice on a proper tracing solution, we are happy to assist.

Applications

- Roof piping in shipbuilding.

- Piping and/or transport pipelines in the industry.

- Other piping and associated components wherein the product or the liquid may not soldify or freeze.